Truth about Laser Cut Soap Stamps

If you are looking for sopa stamps to emboss logo or branding onto your products, this is what you should know.

Easiest way to produce stamps is with CO2 or YAG laser machine. Our machine is as big and as powerful as it gets but having state of the art machine is not enough! There are various settings and various client requirements. Before you order your stamps you should know how they are mad and what you will get and perhaps what you really need for your own unique situation.

Laser engraved products are achieved by having a laser beam of certain wave length (focused light) burn out a material line by line until image is formed. Its similar to inkjet printer instead of putting ink we will burn material. When indicated material is removed we end up with engraved product similar to the soap stamp model shown below. 3D model shows 2.5×1″ stamp with regular settings which on average results 1/16- 1/8″ letter elevation and about 1/8″ (3mm) base plate.

If you look closely you will see bold lettering (mirrored vertically) elevated over base plate. Those letters will emboss into your soap stamp or candle and leave the imprint. When ordering your custom soap stamps you should notice lines on back plate. They are important side affect if laser production for engravings over 1/16″ (1.5mm) elevations. As laser power wave slightly as beams burns material, certain pats of material a engraved/burned deeper and some others not so at the end there is a relive like waves, they are very small and not significant but they are there. For better visualization we build this 3D model. As results and presence of those waves you need to be sure that you don’t over press your stamps an “waves” will also be embossed to your soap brick.

Waves can be removed during production at special request. Ex cutting stamp like regular office stamp with 1/16″ elevation will have minimal or no waves of surface of acrylic or rubber material. Which means you can press very hard and deep to the pe material without worry of base plate touching the soap.

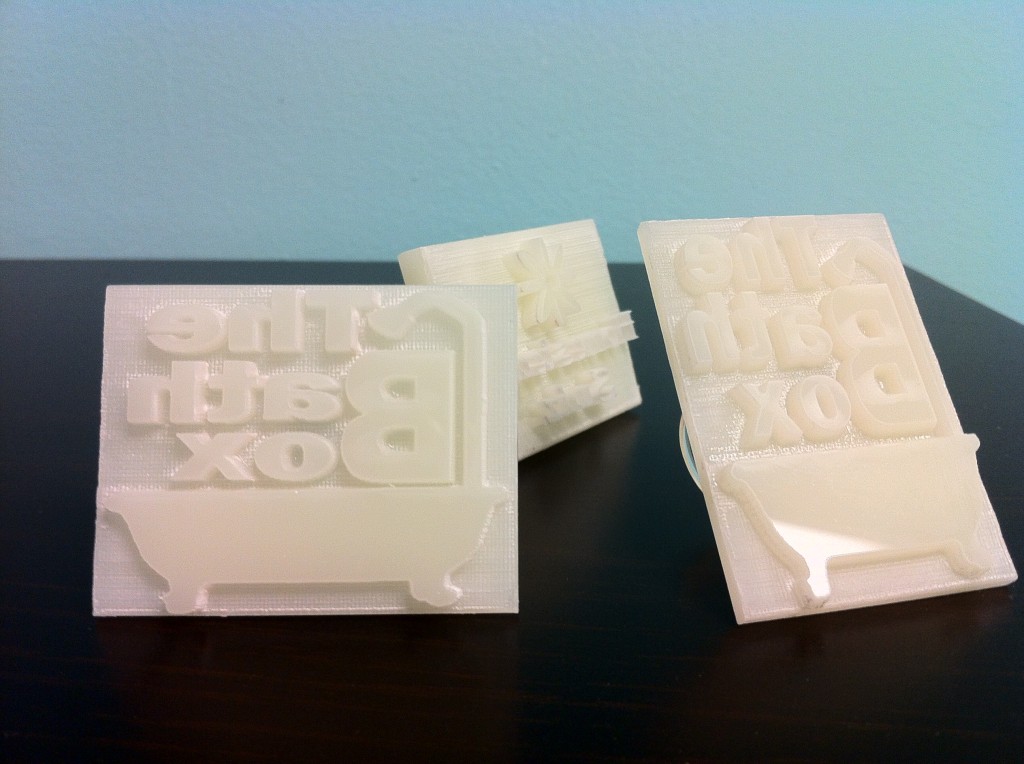

Not so over scare you in your decisions, soap stamp above is actual stamp we produces. It has base plate waves too! As you can see them they are barely visible.

Now that you know what to expect it terms of base plate, lets cover 2 types of engravings we do most for hand made soap and lotion bars.

Shallow (Regular) VS Deep Engraving

- Regular Engraving – is reasonably fast produced plexi glass based stamps. They are most popular in hand made soap community. They are good for softer soaps that need light touch to imprint company’s custom artwork . Artwork elevated about 1/16-1/8″ over the base plate.

- Deep Engraving – if you want your artwork or lettering to go very deep in the soap material or candle wax then we recommend deep engraving. Our acrylic base plate will be almost fully used up and very often letter elevation will be near 1/4″. To reinforce your stamp we sandwich the stamp plate on another 1/4″ plexi plate. Deep engraving works perfectly for text stamps or stamps with minimal graphics. Stamps with extensive graphics will be done as mix between deep and regular in order to achieve best quality of output.Photo above shows sandwiched custom made deep engraved plexiglass soap stamp.

Below you can see render model for both deep and regular engraved stamps.

If you are looking at more serious productions you many want to consider metal stamps (press forms) or silicon molds. Main advantage of metal stamp over plexiglass (acrylic) soap stamps is that metal soap stamp is machined on CNC machine where material removal carbide bits are carving on the same height at all times which ensures perfect surface of back plate. Perfectly carved metal or wax module will endure that if stamp is over pressed the surface of the soap will still be smooth. Also obvious advantage of metal stamp is durability and shelf life. Metal stamps are almost impossible to brake so under normal circumstances they should serve you forever. The disadvantage if metal soap stamp is high cost and slow turnaround. Metal stamp may take 3 weeks to manufacture where acrylic stamp can be done in same day if needed.

Photo above shows sample rendering of metal stamp made of regular brass. If you want to cast your sopa in pre-made forms we can recommend silicone molds. they can have multiple cavities and have your logo be part of the mold already. Molds are the fastest way for mass production you can have 50 cavities and have 50 soaps made at a time. Obviously custom silicone molds are priced with production prices.

Photo above shows sample rendering of metal stamp made of regular brass. If you want to cast your sopa in pre-made forms we can recommend silicone molds. they can have multiple cavities and have your logo be part of the mold already. Molds are the fastest way for mass production you can have 50 cavities and have 50 soaps made at a time. Obviously custom silicone molds are priced with production prices.

Weather you are small organic soap enthusiast, small business or growing medium size company we can always help you add brand identity to hand made and natural products. You can order acrylic, metal or silicon modules on our order page specifically designed for soap accessories orders. If you have any questions free free to call (646-657-2626 ext 3 ) us or use contact page

Ready to order your custom made soap stamp? Click on button below

Hi

Iran in touch with you if possible or DXF files Bzam submit CDR for laser cutting.

Thanks

Hi we can work with both DXF and CDR files. Im not sure if USA trade laws permit us to ship anything to Iran though.

I need a custom logo created for my soap business. My web address is listed above. My logo is in the center, towards the top of the home page. My soaps aren’t very fancy and they are, roughly, 2 x 3 inches in size. I don’t want a handle. I need to be able to hit it with a mallet. I have this logo on a jpeg file. You come highly recommended by other soap professionals and I hear that you treat people well.

hi for your specks you need deep stamp and wood backer so you can use mallet on your stamp. Please use our contact form to submit your logo

Hi Lazer-Cut team,

I make cold process soap and would like a high quality low cost stamp; deep in-print is okay. However, I produce about 800 pieces per batch. What do you recommend for me. Ideally moulds would be best because I do not have to hand cut the soap block with wire. Please advise.

Regards,

Peter

Hi custom mold is not cheap, more like expansive, for 800pcs it might be easier to use generic mold to get shape of the soaps and then hand stamp the logo or use press to automate stamping a little. I can stamp 1000pcs soaps per day with arbor or drill press very easily as long as there is other person helps moving soaps in and out.

I ordered my first soap stamp from Laser Cutz and I’m here to say…..”It’s Awesome!!” He did a great job! Looks stunning on my soaps!! I highly recommend!!

~Garnett~

Do you ship your products to Dubai?

yes sure

I am very interested in having a custom soap stamp made. I don’t have a design. Do you design? I have an idea in mind.

we can setup art for you

I am interested in getting a laser cut soap stamp for my hand made soap

sure we can do your custom laser cut stamp

please use this page to place order: https://cms.lasercutz.com/order/stamps

Hello

I would like to purchase a custom stamp for my soaps with my logo on it. I have briefly looked through your site but didn’t see any information on how to place an order. Will please let me know how to order a stamp, cost, etc. Thank you

Hi you can place stamps order here: https://cms.lasercutz.com/order/stamps

just fill in size, type of stamp you like and upload artwork. Page will give you price